NOIA Member Spotlight

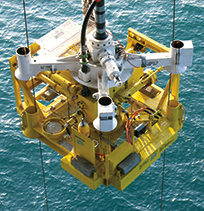

Dril-Quip, Inc. is one of the world’s leading manufacturers of offshore drilling and production equipment that is well suited for use in deepwater applications. Headquartered in Houston, Texas, Dril-Quip has major manufacturing facilities in the United States, Brazil, Scotland, and Singapore. Dril-Quip also provides technical advisory services, reconditioning services, and running tools for use in connection with the installation and retrieval of its products.

Dril-Quip’s manufacturing operations are vertically integrated, with the company performing essentially all of its forging, heat treating, machining, fabrication, inspection, assembly, and testing at its own facilities. The company has developed its broad line of subsea, surface, and offshore rig equipment primarily through internal product development efforts. These drilling and production products can be packaged to provide integrated system solutions for offshore exploration and production activities. Examples include:

- Subsea Well Systems – Dril-Quip supplies equipment for offshore exploration applications which include specialty casing connectors, subsea wellhead equipment, mudline suspension equipment, and liner hangers.

- Dry Tree Systems - The Company also supplies Dry Tree completion systems to fixed platform and floating production platform applications which include specialty casing connectors, subsea and surface wellhead systems, templates, liner hangers, tie-back connectors, production risers, production riser tensioners, and surface production trees.

- Subsea Completion Systems – Another Dril-Quip product is subsea completion systems for subsea field developments which include specialty casing connectors, subsea wellhead systems, liner hangers, templates, subsea completion trees, subsea controls, flowline connection systems, PLEM’s, PLET’s and flow-control manifolds.

- Offshore Rig Equipment – Finally, Dril-Quip produces a line of rig equipment to offshore drilling vessels that include Diverter Systems, Marine Drilling Riser systems and wellhead/BOP connectors.

Advanced Product Quality Planning

Dril-Quip also operates under a quality management system called APQP (Advanced Product Quality Planning) that incorporates a structured method of assessing design and manufacturing characteristics that govern the fit, function and service life of the product. This assessment is the foundation of design and manufacturing process controls that are used to assure a safe, reliable product that meets or exceeds performance and customer expectations.

Dril-Quip also operates under a quality management system called APQP (Advanced Product Quality Planning) that incorporates a structured method of assessing design and manufacturing characteristics that govern the fit, function and service life of the product. This assessment is the foundation of design and manufacturing process controls that are used to assure a safe, reliable product that meets or exceeds performance and customer expectations.

For more information on Dril-Quip visit click here